In fluid systems – whether it’s heating networks, cooling circuits, industrial pipelines, or water supply lines – pressure drop is a critical performance factor. Undetected or excessive pressure drops can lead to higher energy consumption, equipment strain, reduced system efficiency, and even unexpected breakdowns. SmartSenser™ provides businesses with real-time, intelligent monitoring and management of fluid pressure drop, helping to maintain system health, cut running costs, and prevent costly downtime.

The Problem: Hidden Pressure Drops Drain Efficiency and Budgets

In any system where fluids circulate, friction, pipe blockages, corrosion, or equipment faults can cause pressure to drop between the pump and the delivery point.

When this happens unnoticed, it can result in:

- Pumps working harder than necessary, increasing energy consumption and wear.

- Insufficient flow at endpoints, affecting heating, cooling, or process performance.

- Higher maintenance needs and premature equipment failure.

- Inefficient system balancing, driving up operational costs and carbon footprint.

Traditionally, engineers rely on periodic manual checks, which often miss gradual pressure losses until they become serious problems.

The Solution: Smart, Automated Pressure Drop Monitoring

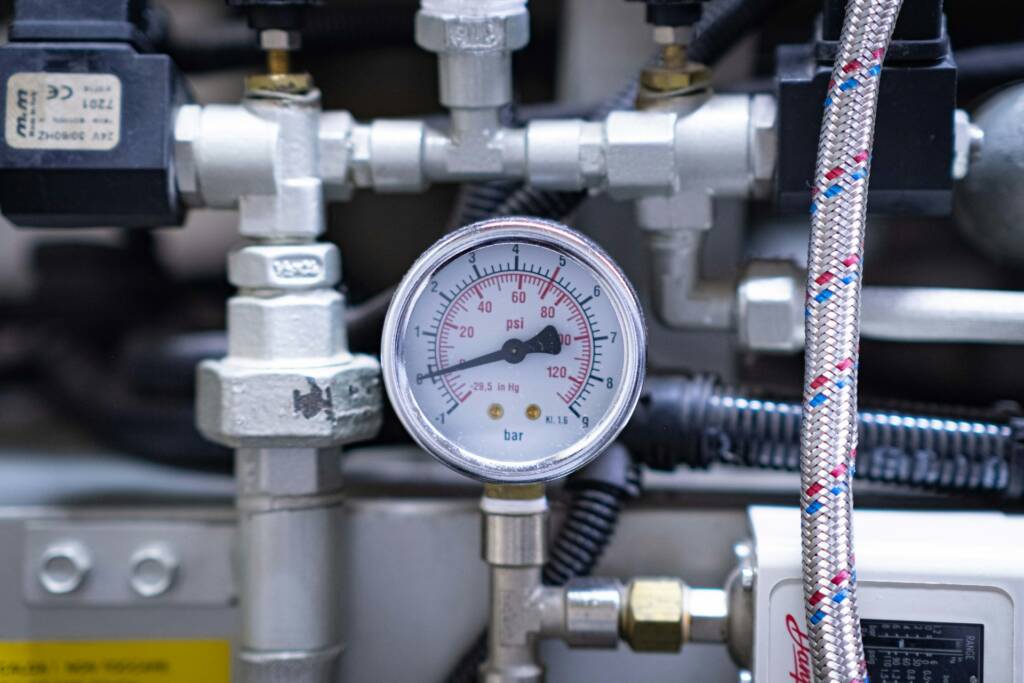

SmartSenser™ brings automation and intelligence to pressure drop management. Installed at key points along fluid circuits, SmartSenser™ continuously measures pressure levels and flow rates.

When it detects a pressure drop outside normal parameters, SmartSenser™ immediately:

✔ Alerts maintenance teams or facility managers in real-time.

✔ Provides data pinpointing where the drop is occurring.

✔ Logs historical pressure trends to help identify recurring issues.

✔ Supports predictive maintenance by flagging gradual performance decline.

By monitoring fluid pressure dynamically, SmartSenser™ helps keep systems balanced, efficient, and cost-effective.

How SmartSenser™ Solves Real-World Pressure Drop Challenges

Prevents Excessive Energy Use

By catching pressure drops early, SmartSenser™ stops pumps from overcompensating, saving on electricity and extending pump life.

Maintains System Performance

Reliable pressure means heating, cooling, or fluid delivery stays consistent, avoiding performance dips that affect operations or occupant comfort.

Reduces Unplanned Downtime

SmartSenser™ spots developing problems before they cause breakdowns, allowing for planned maintenance instead of emergency repairs.

Cuts Maintenance Costs

Targeted, data-driven maintenance reduces unnecessary service visits and helps prioritise work based on real system conditions.

Optimises System Balancing

Continuous data makes it easier to balance complex pipe networks, improving flow efficiency and reducing bottlenecks.

Supports Sustainability Goals

By maintaining optimal system efficiency, businesses reduce wasted energy and lower their carbon footprint.

Real Savings: Efficiency That Pays for Itself

Companies using SmartSenser™ to monitor fluid pressure drop have seen notable reductions in energy consumption, pump repair costs, and emergency call-outs. Many recover their investment quickly through lower operating costs and extended equipment lifespan.

Stay in Control of Pressure Drop with SmartSenser™

Unnoticed pressure drops silently undermine fluid system efficiency and reliability. SmartSenser™ provides the continuous, intelligent monitoring needed to detect, diagnose and address these drops proactively. The result? Lower costs, smoother operations, and a fluid system that runs exactly as it should – all day, every day.